DETECTABLE BLACK PLASTIC TECHNOLOGY

Black plastic has always been a challenge for recyclers, but CuBE Packaging has emerged as a leader in recyclable black plastic technology. Our food containers use detectable black plastic to help automated sorting devices identify and separate these items like never before.

ACCOMPLISHING THE IMPOSSIBLE

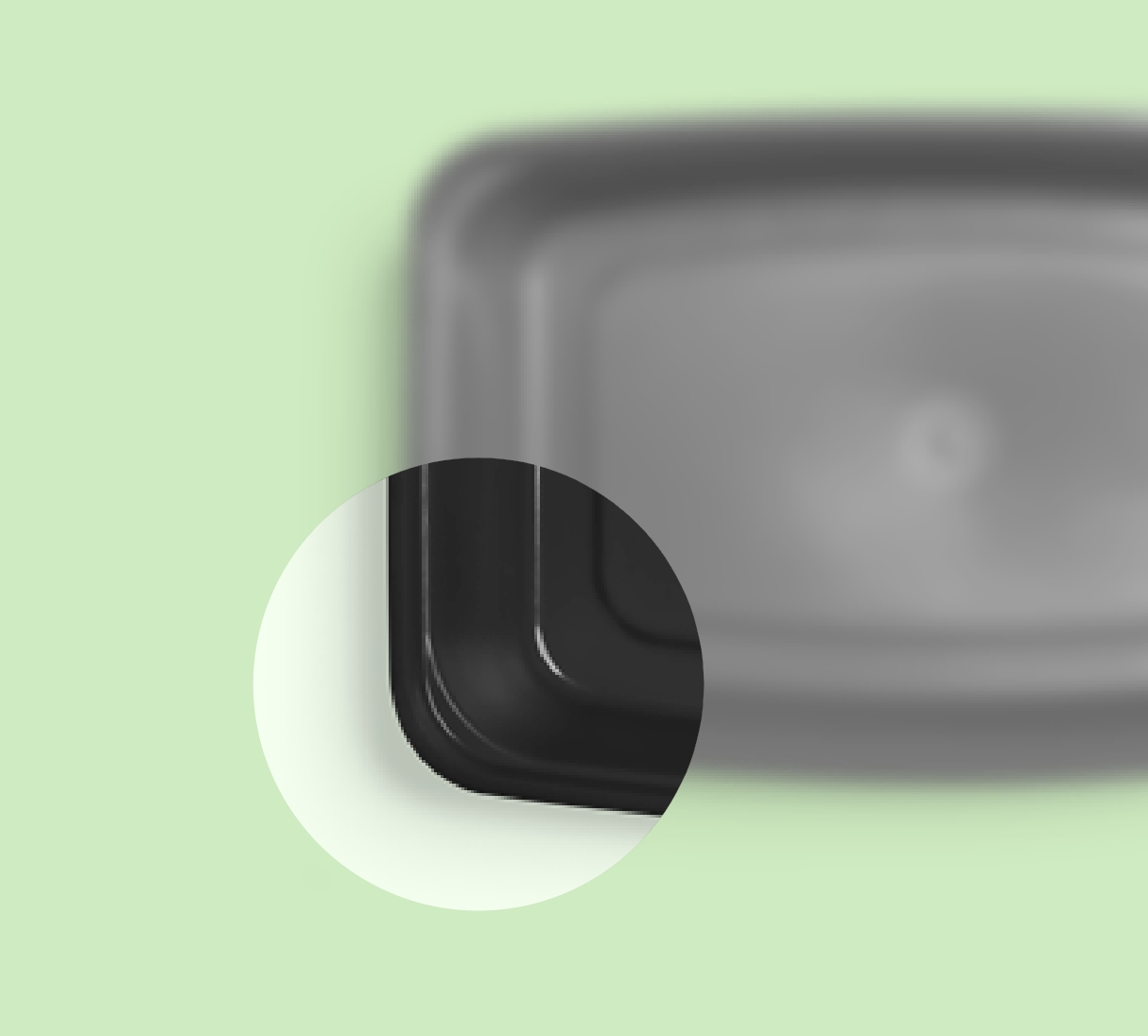

Black plastic disrupts recyclers because infrared scanners rely on detecting and sorting materials based on their molecular composition — and black plastic absorbs infrared light. We’ve engineered CuBEware to be transparent to infrared, driving a quantum leap in recyclability.

UNDERSTANDING DETECTABLE

BLACK PLASTIC

1

What is it?

Our innovative black plastic technology incorporates detectable pigments, enabling automated recycling systems to accurately sort our containers based on their distinct molecular composition.

2

Why is it important?

Our technology is crucial to help reduce landfill waste and enhance efficiencies for the recycling processes.

3

How does it work?

Automated recycling systems measure plastic molecular weight distribution through infrared absorption. Our black plastic is designed to be transparent to these systems for efficient sorting.

4

Why is it superior?

Aside from poor recyclability, conventional carbon black pigments in other plastics pose long-term health risks. They irritate the eyes, nose, throat, and lungs, especially in industrial settings.

LET’S

CONNECT

QUESTIONS?

WE’RE HERE

TO HELP.

"*" indicates required fields